Raw-material compliance begins at the smelter: we source only prime-grade, low-carbon billet certified to EN 485-2/ASTM B221 and subject each batch to spectrographic verification, porosity indexing and homogenisation profiling prior to extrusion. Our ISO 9001- and IATF 16949-accredited plant deploys closed-loop, PLC-controlled presses (1,600 T–6,800 T) with online dimensional laser gauging and AI-driven cavity-pressure monitoring, achieving Cpk ≥ 1.67 on critical-to-quality (CTQ) dimensions. Down-stream processes—CNC, thermal break assembly, anodising, PVDF and powder coating—are governed by ISO 14001 and Qualicoat/Seaside Class 2.0 standards, supported by salt-spray, Q-SUN xenon and cyclic acid condensation testing. Certificates of compliance, PPAP Level 3 documentation and digital test dossiers accompany every shipment, guaranteeing traceability from billet number to finished profile.

Quality Assurance

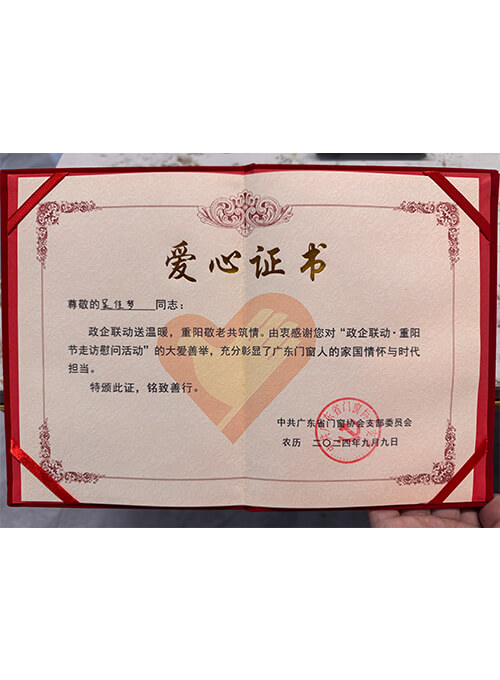

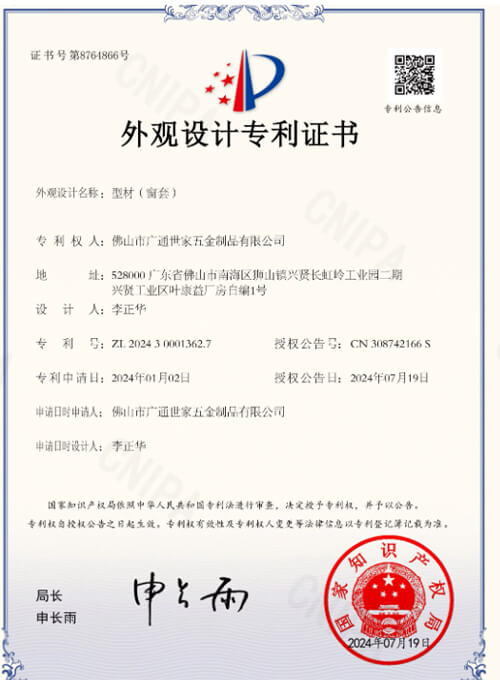

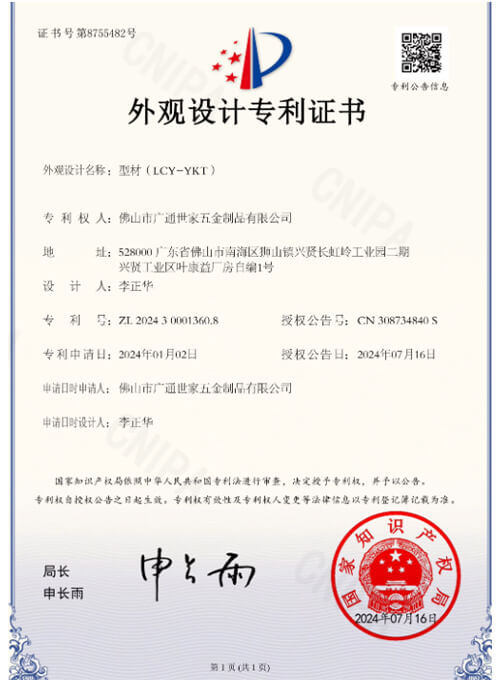

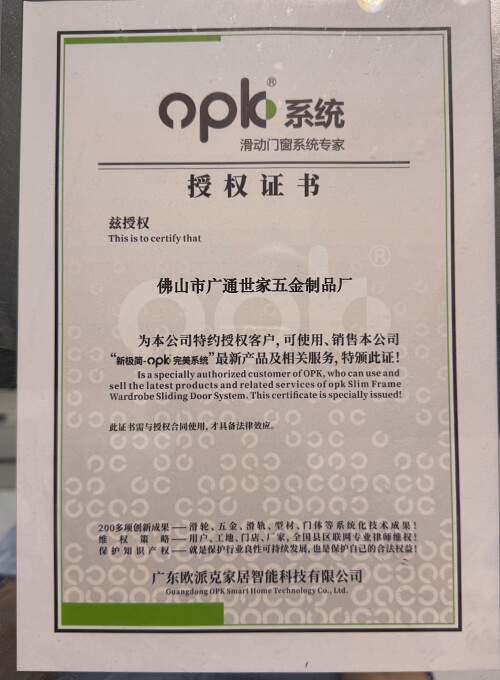

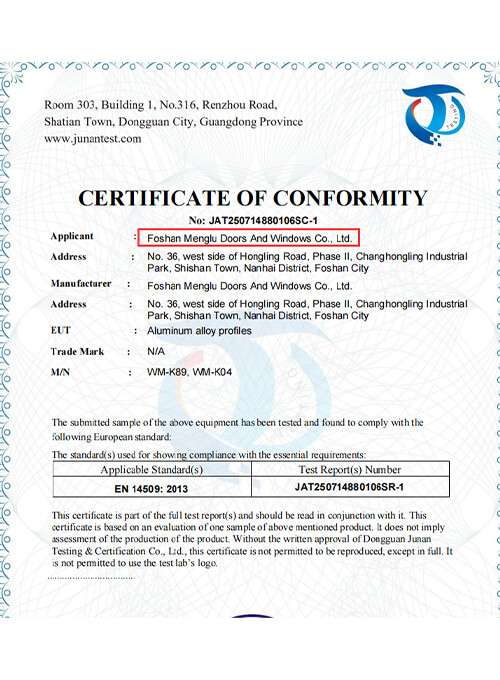

..Our Certificate..

certificate